Balance Weave Belts

A fabric consisting of alternating left and right hand spirals, which are joined together with the insertion of a crimp rod. Because of its wide range of opening sizes and its easy tracking capabilities, the balanced weave is the most commonly used mesh. These belts are widely used in the food processing, heat treating and insulation industries.

Advantages

- Low ultimate cost.

- Straight belt travel.

- Easily installed and aligned.

- Easy to repair damaged sections.

- Most flexible for use with small diameter pulleys.

Double Balanced Weave Belts

A fabric consisting of pairs of interlaced right and left hand spirals joined by a crimped or straight rod connector in a manner so that the pairs of spirals are interspaced by the adjacent spirals. This construction provides greater strength and larger clear openings than the balanced weave design. It is excellent for drying, washing, chemical treating and high temperature applications.

Advantages

- Most effective opening for air circulation and liquid drainage.

- Will operate under extremely high stresses with little contraction in width or longitudinal stretch.

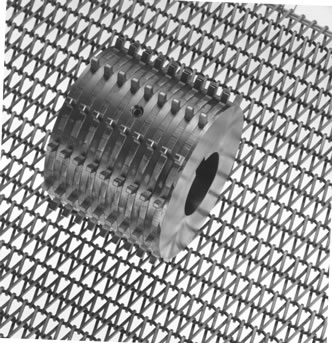

Compound Balance Weave Belts

A fabric consisting of alternation right and left hand spirals nested together and joined by three or more straight rods. The tight weave and smooth surface make it ideal for the conveying of small parts and for transfer operations. It is a mesh that is preferred in the baking, heat treating, and quench tank operations.

Advantages

- Smallest openings available.

- Dense, smooth conveying surfaces.

- Minimum belt elongation and width contraction.

- Uniform heat distribution.

Conventional Weave Belts

A fabric consisting of a series of either right or left hand spirals each turned into the preceding spiral to form a continuous belt. The open mesh provides for maximum drainage and air circulation.

Balance Weave/Straight Wire Belts

Very similar to the balanced weave except that spirals are joined together by a straight rod. This allows for the spirals to be more closely wound, resulting in a stronger construction. These belts are popular in foundry applications.

Advantages

- Smooth carrying surface.

- Permits handling of small parts and products.